14.4 Waste to Energy

The two main ways to convert energy to waste are through combustion of the methane in the landfill gas and direct incineration of the waste itself.

As noted above, landfill gas is a mixture of mostly carbon dioxide and methane. Methane is a much more powerful greenhouse gas than carbon dioxide. It also represents an explosion risk around a landfill, so it cannot just be released into the atmosphere. The simplest solution is to flare the gas and convert the methane to carbon dioxide.

A better solution is to use the landfill gas as a fuel source for generating electricity or for heating buildings or other facilities. An example of a landfill-gas to energy plant is shown on Figure 14.4.1.

Waste incineration is widely used as alternative to landfills as about 90% of the typical municipal waste stream is burnable, including: organics, paper, plastic, hygiene products, construction waste, some of the hazardous waste, and rubber. The remaining inflammable material includes glass, metal and electronics. Most modern waste incineration plants are designed to produce electricity. In fact, depending on the local price of electricity, a waste-to-energy plant may be able to recover much or all of its operation cost through the sale of electricity. On top of that energy revenue, the process should provide for the recovery of metals, and some other materials that have value.

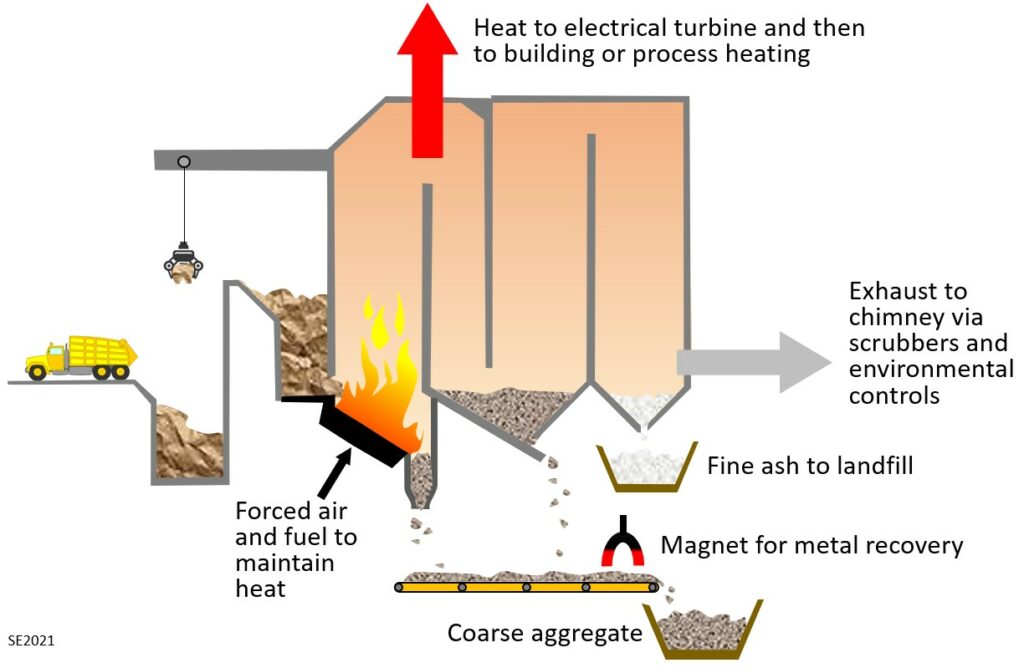

A schematic of a typical waste-to-energy plant is provided on Figure 14.4.2. Unsorted waste is dumped from the waste truck into a pit and then transferred to the incinerator hopper with a grappling crane. Forced air is used to maintain hot incineration and some other fuel may be used to ensure that the temperature doesn’t drop below a certain level. Coarse non-burnable material is recovered and may be used as aggregate. A strong magnet is used to separate metals from that stream. Finer fly ash is recovered and likely sent to a landfill. The volume of material that has to be landfilled is typically 10 to 15% of the original volume of the waste. Heat is extracted to power a steam turbine for electricity generation, and leftover heat may be used to heat nearby buildings or greenhouses or for a process that requires heat. Exhaust gases are passed through scrubbers and other air-pollution control systems.

Most of the hundreds of existing waste-to-energy operations around the world use technologies similar to that described above, but there are alternatives that involve the production of gaseous or liquid fuels from waste by heating, fermentation or distillation. Some of these have the potential to produce more energy than is possible through direct combustion of the waste, but they also require that waste materials be sorted beforehand.

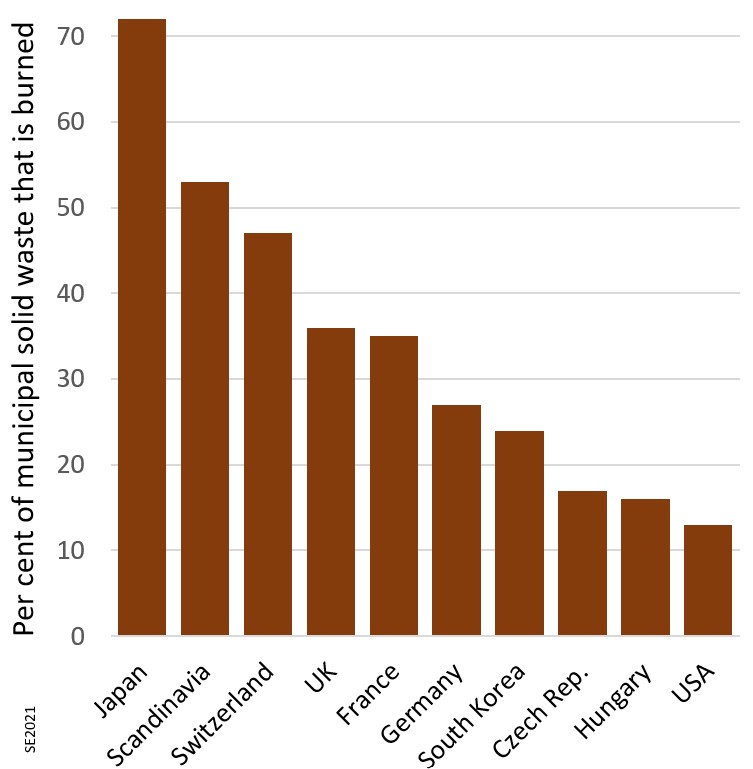

Japan has the highest proportion of waste-to-energy diversion of solid waste, at around 74%, followed by several European countries in the range of 30 to 50% (Figure 14.4.3).

Media Attributions

- Figure 14.4.1 Photo by Steven Earle, CC BY 4.0

- Figure 14.4.2 Steven Earle, CC BY 4.0, based on a drawing at US Energy Information Administration. (n.d.). Biomass explained: Waste-to-energy (Municipal Solid Waste). https://www.eia.gov/energyexplained/biomass/waste-to-energy.php

- Figure 14.4.3 Steven Earle, CC BY 4.0, based on a data at US Energy Information Administration. (n.d.). Biomass explained: Waste-to-energy (Municipal Solid Waste). https://www.eia.gov/energyexplained/biomass/waste-to-energy.php